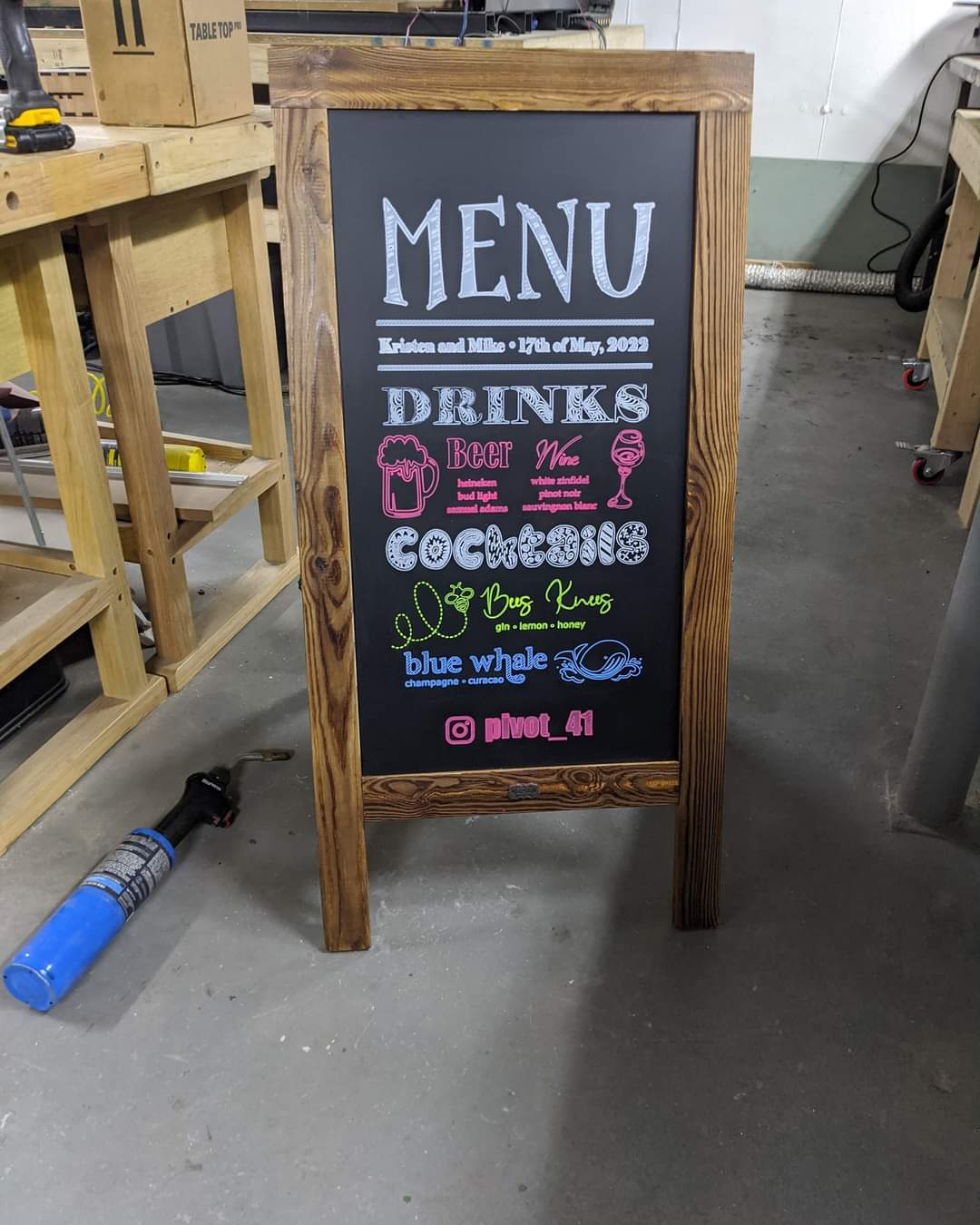

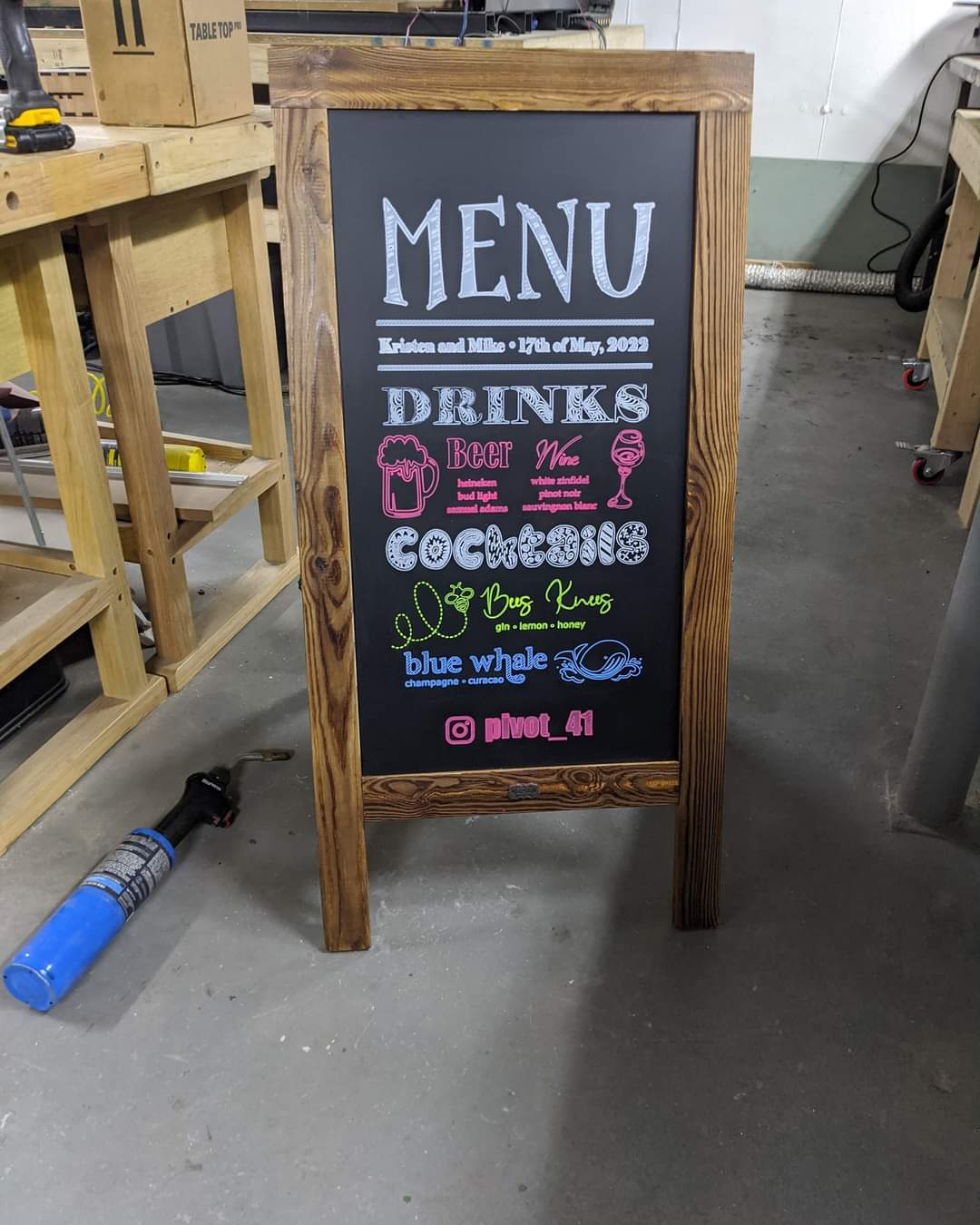

We thought it would be cool to let Ross (our CNC machine) have a break from the hard work and give him a chance to express his artistic self. We designed a spring loaded pen plotter for him, and……here are the results!

We thought it would be cool to let Ross (our CNC machine) have a break from the hard work and give him a chance to express his artistic self. We designed a spring loaded pen plotter for him, and……here are the results!

Customer: Tennis Week-end Warrior

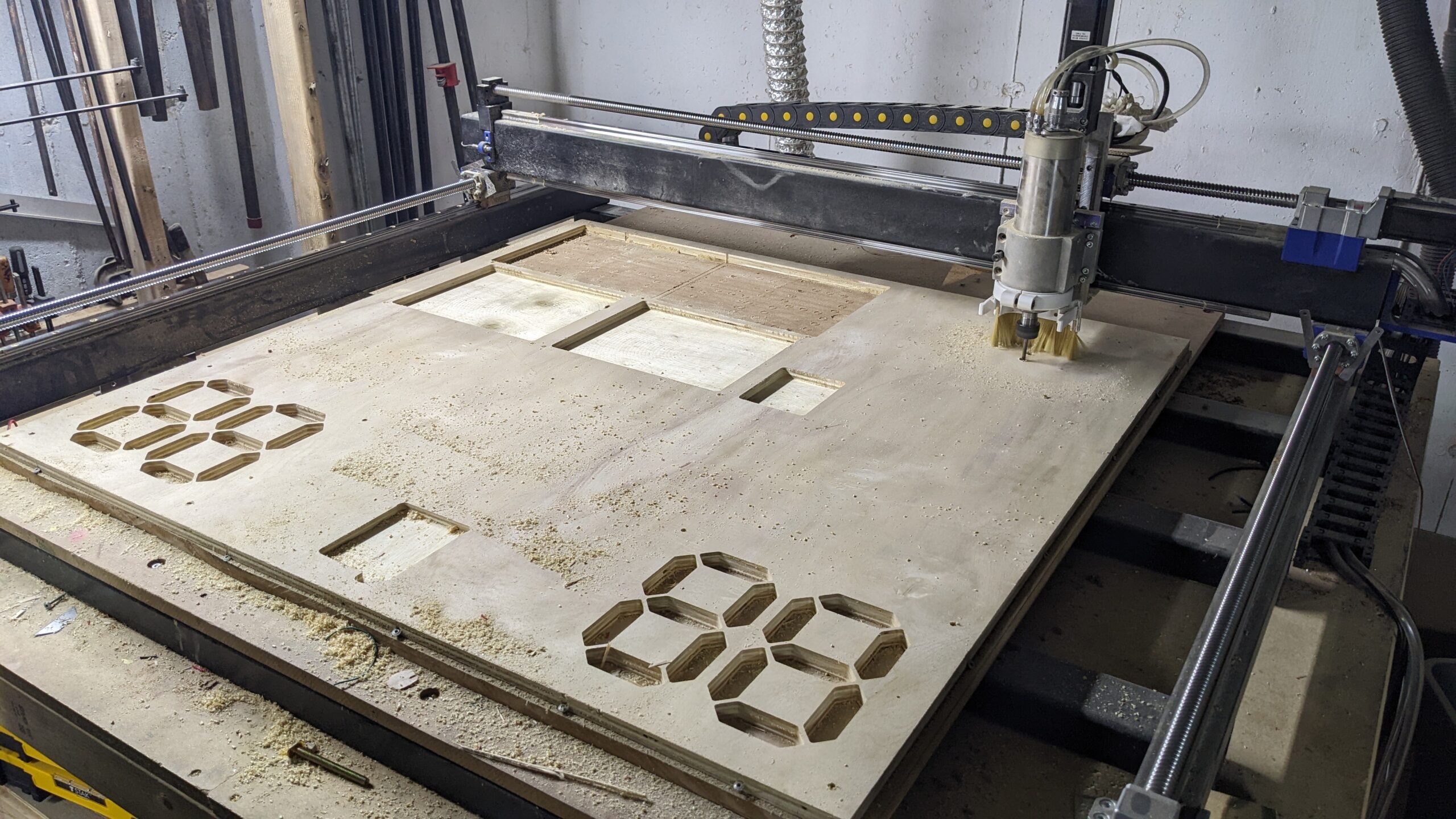

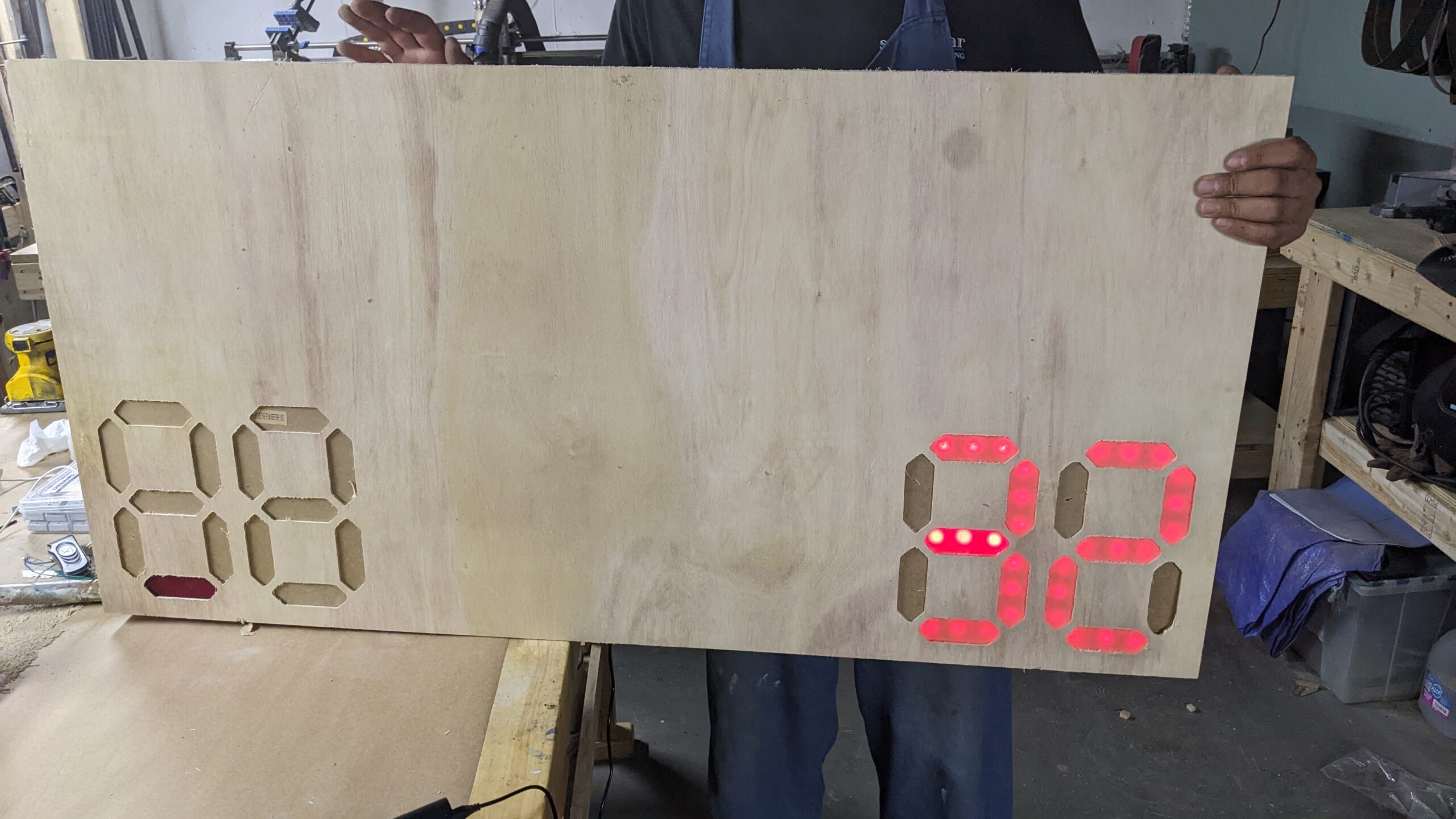

A friend of ours commissioned us to build a full sized scoreboard for his family as a Christmas gift. There were a couple things that made this project special. For starters, there are no plug-and-play electronics available to create the segmented LED display with the look and size we were shooting for– so we decided to make our own using some outdoor LEDs, a wireless remote control, and an arduino micro-controller. Additionally, this thing was going to live outdoors, so we had to be thoughtful about waterproofing the wood and electronics.

We did the majority of the heavy lifting with our CNC, with the majority of the components being carved out of wood and then snapped together. We made our 7-segment LED displays by diffusing outdoor WS2812b LED strip with red acrylic which we coarsely sanded and then cut on our laser cutter. Lastly, we made letters using a vinyl cutter, and coated with varnish to get a glossy, polished, water-proofed finish.

Customer: Hot Rod Enthusiast

Sometimes just because you think you can do something, doesn’t mean you should. This was our first project— and it was right within our wheel house. The charter was to 3D print a logo for this guy’s awesome hot rod. After a few iterations and some time with the airbrush, it was very clear we wouldn’t be able to “fake” it with plastic, and not look completely out of place ontop of this one-of-a-kind, perfectly painted custom Ford hot-rod.

So when we said we would make it, we really meant we would build a CNC machine, learn how to use it, and fail nothing short of 20 or 30 times before we got something we felt good about.

We routed the logo in 6061-0 aluminum stock, casted it with color-matched epoxy, and fortunately met a master metal worker and awesome guy named David who helped us figure out how to bend it it to perfectly match the hood of the car.

This simple little badge reflects a lot of little lessons and marks the start of our journey into custom design work.

Customer: Shank’s Clubhouse

Its gratifying (and a little nerve-racking) to work with high quality materials. We started this project with a gorgeous piece of live-edge cherry. Shank’s logo was routed out on our CNC machine machine, and then casted using black-dyed epoxy. After finishing the wood, we back-lit the cut-through segments with super-bright LEDs.

Customer: Newport Craft Brewing and Distilling

Thomas Tew Rum is distilled in Newport, named after our very own, very infamous pirate.

This is was one of the largest graphics we’ve run on our CO2 laser to date and it the perfect opportunity to use both of our big boy CNC and Laser Cutter in tandem. We drilled and cut just about everything on the CNC and then used our laser cutter to engrave logos on the board and the chips.

We were after the natural, distressed oak barrel look and stumbled on a pretty cool technique in the process. As it turns out, I’d you get your depth settings dialed in, you can actually engrave right past the stain, revealing the original lighter surface.